Research & Development

Engineering

We are a specialized engineering design office for medical devices, providing end-to-end expertise in firmware, electronics, mechanics, and laser systems.

Our team supports R&D and product development from concept to industrialization, ensuring safety, performance, and compliance with international medical standards. We combine technical depth with regulatory rigor to help manufacturers bring reliable, innovative, and audit-ready devices to marke

Our expertises

Embedded Software

We accompany you throughout the lifecycle, from early experimentation to robust, production-grade embedded software.

Requirements, Architecture & Design

Requirements engineering: Collaborating with your R&D team to define functional and safety requirements for the embedded software, ensuring alignment with IEC 62304 and medical device regulations.

System architecture: Designing the embedded system structure, including hardware/software partitioning, processor and microcontroller selection, and operating system strategy.

Real-time & safety-critical design: Identifying time-sensitive and safety-critical functions, defining scheduling strategies, and implementing fault-tolerant mechanisms.

Risk & compliance alignment: Connecting technical design choices with ISO 14971 risk management, ensuring hazards are addressed and traceability is maintained.

Design documentation: Producing high-level and low-level design documents with full traceability, suitable for inclusion in regulatory submissions (FDA, EU MDR, Notified Bodies).

Firmware & Embedded Application Development

Microcontroller firmware: Development on MCUs (ARM Cortex-M, STM32, NXP, Nordic, Renesas, TI…) using bare-metal programming or real-time operating systems (FreeRTOS, Zephyr).

Embedded Linux platforms: Firmware and system software for high-performance CPUs (e.g. i.MX8), including kernel drivers, device tree configuration, and integration of medical peripherals.

Debugging & optimization: In-depth analysis and problem-solving with JTAG/SWD, oscilloscopes, logic analyzers, and trace tools, ensuring stable and deterministic operation.

Secure bootloaders & updates: Implementation of secure boot mechanisms and over-the-air (OTA) update systems, ensuring safe, traceable, and maintainable software in the field.

Lifecycle support: Investigation of legacy firmware, refactoring for compliance, bug corrections, performance improvements, and documentation updates for regulatory submissions.

Verification, Validation & Maintenance

Test design and execution: Development and execution of unit, integration, and system-level test cases, with full traceability back to software requirements.

Simulation and validation environments: Use of Hardware-in-the-Loop (HIL) and Software-in-the-Loop (SIL) setups to validate firmware early in the development cycle, reducing risks and accelerating compliance readiness.

Verification reporting: Preparation, execution, and delivery of complete software verification reports, covering test protocols, results, and compliance evidence.

Regulatory documentation: Production of verification and validation documents aligned with IEC 62304, supporting audits and submissions to regulatory authorities (FDA, EU MDR, Notified Bodies).

Safety & Compliance

We ensure that all firmware development for medical devices is conducted under strict regulatory frameworks, with risk management and safety at the core of our engineering process.

Standards-driven development: Full alignment with IEC 62304 for the medical software lifecycle and integration with ISO 13485 quality management systems.

Risk management: Application of ISO 14971 principles to identify hazards, assess risks, and implement mitigations directly in firmware design and implementation.

Safety mechanisms: Integration of watchdogs, redundancy strategies, failsafe states, error detection and recovery routines to ensure patient safety under all operating conditions.

Cybersecurity: Implementation of secure coding practices, encryption, authentication, and secure boot/update mechanisms to protect against vulnerabilities, in line with FDA guidance and EU MDR cybersecurity requirements.

Regulatory support: Production of compliance evidence, traceability artifacts, and safety documentation to support audits and regulatory submissions.

Electronic design

We design and integrate reliable electronic systems for medical devices, ensuring precision, safety, and compliance from concept to production.

Hardware Architecture & Circuit Design

Definition of electronic system architectures to meet functional, safety, and regulatory requirements.

Design of analog and digital circuits for control, power management, sensing, and actuation in medical devices.

Selection of medical-grade components with lifecycle, reliability, and compliance considerations (e.g. AEC-Q, IEC, ISO-certified parts).

Signal integrity and EMC-aware design to meet IEC 60601 and related safety standards.

PCB Design & Layout

Schematic capture, PCB layout, and routing for multilayer boards.

Design for high-speed signals, low-noise analog front-ends, and mixed-signal integration.

Miniaturization and optimization for portable/wearable medical devices.DFM (Design for Manufacturability) and DFT (Design for Test) practices to ensure smooth transition to production.

Prototyping, Testing & Validation

Rapid prototyping of PCBs for feasibility and early evaluation.

Electrical testing, debugging, and validation using oscilloscopes, logic analyzers, and specialized measurement equipment.

Environmental and stress testing (temperature, vibration, EMC pre-compliance).

Verification against safety standards (e.g. IEC 60601 for electrical safety and electromagnetic compatibility).

Industrialization & Lifecycle Support

Support for transition from prototype to industrial production, including collaboration with EMS (Electronic Manufacturing Services).

Component lifecycle management and obsolescence monitoring.

Support for regulatory submissions with complete technical documentation (schematics, BOM traceability, test reports).

Continuous improvement and redesign for reliability, cost optimization, or new regulatory requirements.

Mechanical Design

We support you through every stage of development — from concept and prototype to finely tuned, production-grade mechanical solutions.

Product Architecture & 3D Design

Definition of mechanical architectures to meet functional, ergonomic, and safety requirements of medical devices

3D CAD design of housings, enclosures, moving parts, and subassemblies with attention to usability and sterilization needs.

Design for manufacturability (DFM) and design for assembly (DFA) principles integrated from the start to ensure cost-effective and reliable production

Material Selection & Compliance

Selection of biocompatible and medical-grade materials (ISO 10993) for components in contact with patients or fluids.

Design considering sterilization processes (autoclave, gamma, EtO) and regulatory constraints.

Surface treatments, coatings, and seals adapted to hygiene, wear resistance, and safety-critical usage.

Prototyping, Testing & Validation

Rapid prototyping (3D printing, machining) to validate ergonomics, assembly, and functional performance.

Mechanical testing: strength, fatigue, vibration, drop, and environmental testing in line with IEC and ISO standards.

Thermal management, sealing (IP ratings), and structural reliability validation.

Support in preparing documentation for verification and regulatory submissions.

Industrialization & Lifecycle Support

Optimization of designs for mass production methods (injection molding, machining, additive manufacturing).

Tolerance analysis and optimization for robust manufacturing.

Support with suppliers and contract manufacturers during ramp-up.

Redesign and continuous improvement to adapt to component availability, new regulatory requirements, or cost optimization.

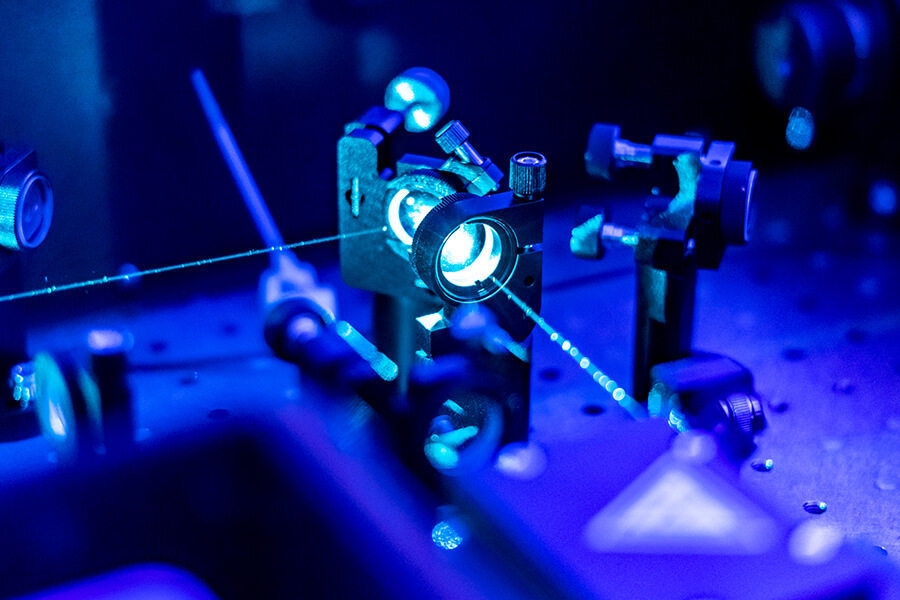

Laser Engineering

We design and optimize laser system architectures that combine precision, reliability, and performance for demanding industrial and medical applications

Laser System Architecture & Design

Definition of laser system requirements and architecture for therapeutic, diagnostic, or surgical applications.

Selection and integration of laser sources (diode, solid-state, fiber, or CO₂) adapted to medical use cases.

Design of beam delivery systems (optics, fibers, scanners) ensuring precision, repeatability, and safety.

Safety & Regulatory Compliance

Implementation of hardware and software safety interlocks in compliance with IEC 60825 (laser safety) and medical device regulations (IEC 60601-1, IEC 60601-2-22).

Risk analysis (ISO 14971) covering eye and skin exposure hazards, energy delivery, and failure modes.

Development of failsafe mechanisms: shutters, redundant controls, watchdog systems, and emergency stop protocols.

Control Electronics & Firmware Integration

Design of laser driver electronics, power supplies, and thermal management systems.

Firmware development for precise control of laser pulses, modulation, and energy delivery.

Integration of real-time monitoring and feedback loops for power stability, wavelength control, and beam positioning.

Prototyping, Validation & Industrialization

Rapid prototyping and lab validation of laser assemblies and subsystems.

Optical and mechanical alignment, beam quality measurements, and stability testing.

Pre-compliance testing for electrical safety, EMC, and laser safety certification.

Support for transfer to manufacturing, including supplier qualification and documentation for regulatory submissions

Discover Our Innovative Approach

At Caducia, we believe that innovation is the driving force behind success. Our team of experts is ready to transform your ideas into tangible solutions. Get in touch with us to explore how we can collaborate on your most ambitious projects.

© All right reserved